What Is A Diamond Plate & What Are Its Uses?

What is a diamond plate? You’ve probably seen these utilized without ever knowing exactly what they are, and how they help.

What Is A Diamond Plate & What Are Its Uses?

There are many materials available for making walking surfaces. Concrete, pavement, wood, tile, and carpet are familiar materials we walk on every day. What’s the purpose of a raised pattern on a metal or plastic surface? The diamond plate will be described in this article, as well as how it is made and how it is used.

Exactly what is a diamond plate?

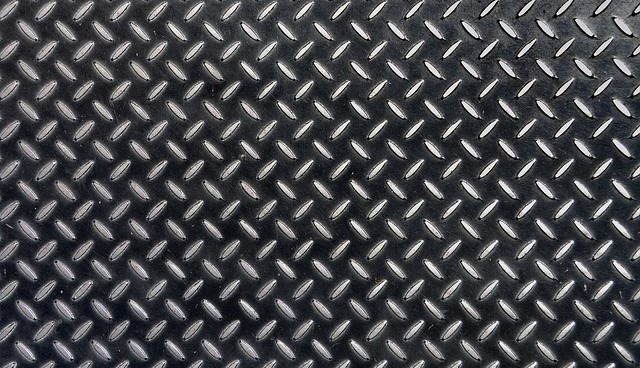

The diamond plate also called the deck plate or floor plate has a raised pattern on one side and is smooth on the other. Diamond patterns and raised areas are variable, as well as their heights. Most commonly, diamond plates are used as a gripping surface on metal stairs.

It reduces the likelihood that someone will slip while walking on the plate because raised bumps on its surface increase friction between a shoe and the surface. The non-slip nature of the diamond plate makes it a perfect choice for walking surfaces.

Diamond plate is made of what?

Metal is typically used for diamond plates. Stainless steel, aluminum, and steel are the most popular metal types used for diamond plate. Interlocking diamond plate sheets can also be created with plastic, in addition to diamond plated metal.

Rubber floor mats also feature diamond plate patterns to help reduce fatigue and improve comfort in workspaces that require extended periods of standing.

Read on to learn more in-depth about the materials used to create diamond plates.

Aluminum

Corrosion is not a problem with aluminum diamond plates. Aluminum deck plates are commonly found in outdoor settings, such as parking lots, loading docks, and stairways, because of their ability to withstand the elements. They can also be found on boats, docks, or marine environments. Due to the ease of cleaning diamond aluminum plates, they are commonly found in kitchens, restrooms, and walk-in refrigerators or freezers. Aluminum diamond floor plates are available in a variety of patterns and finishes and can also be used as decorative elements.

Steel

Diamond plates are made from carbon steel for a variety of reasons. Their strength makes them an excellent structural material. As an alternative to aluminum and stainless steel, diamond plated steel is often less expensive. Among the many commercial and industrial applications for diamond pattern steel include stairs, ramps, trailer floors, vehicle running boards, and truck beds, since it is durable and easy to clean.

Stainless Steel

In terms of diamond plate materials, stainless steel is one of the most expensive ones. However, due to its corrosion resistance, it may be the best choice for an industrial setting or for environments requiring sanitary conditions. Because of its bright finish, the stainless steel diamond plate is also visually appealing.

Plastic

Plastic materials can also be used to make diamond plates. Diamond plate is typically made out of interlocking plastic sheets that can be customized to fit any space, such as garages, offices, utility rooms, and gyms. Various dimensions, designs, and finishes are available for the sheets. Among the positive qualities of plastic diamond plates are their water resistance and stain resistance. It can also be painted to match the environment’s color and used as wall panels.

How does a metal diamond plate get made?

The two most common methods of making diamond metal plates are stamping or hot rolling. In both processes, heat and pressure are used.

A series of large rollers pass room-temperature metal through the stamping process. On one roller, the pattern is smooth and on the other, the pattern is diamond-shaped. In this way, the diamond pattern can be transferred to one side of the metal because of the pressure of the metal passing between the rollers. Diamond plates are commonly made by stamping aluminum.

During hot rolling, the metal is heated using an electronic thermal machine to above its recrystallization temperature before passing through the rollers. The molten metal is then cooled into diamond plate shapes. When making steel diamond plates, heat is commonly used to prevent the metal from developing flaws.

What is the purpose of the diamond plate?

Diamond plates are designed to reduce the risk of slipping by providing traction. Increasing safety is achieved by using a non-skid diamond plate on stairways, catwalks, work platforms, walkways, and ramps in industrial environments. In outdoor environments, aluminum treads are common. Ambulances and firetrucks often have a diamond plate that is used to make the footplates slip-resistant.

In addition to preventing damage from heavy traffic and abrasive chemicals, the diamond plate can be used to protect surfaces. Shipping docks, for example, often have diamond plate floors that can withstand the heavyweight of forklifts transporting materials, and also give warehouse workers a better grip.

Furthermore, the diamond plates can be applied to both metal and plastic. The diamond plate comes in a wide variety of patterns, finishes, and materials, which gives it a varied look for any environment.

Diamond plating: What you need to know

Adding diamond plating to walking surfaces adds traction and slip resistance. Steel, aluminum, stainless steel, and plastic can be used as diamond plates. It is available in a range of patterns and finishes and has a wide range of applications. Now that you know what raised diamonds are and what they do, you will be able to identify them when you see them next time.

The best place to buy diamond plates

Suppliers of specialty metals such as Bushwick Metals sell diamond plate steel. With a vast inventory of high-quality carbon steel structural, decorative, and plate products, Bushwick Metals is the Northeast’s leading wholesale steel distributor. Contact Bushwick today or Request a Quote.